-

Company Info

-

Business Information

-

Sustainability

-

IR NEWS

At the Glosel Group, in order to provide products and services that are trusted and satisfied by our customers, each employee is engaged in activities that place the highest priority on quality from the customer’s perspective.

Basic Philosophy

We will contribute to the expansion of the electronics business and the development of industry in Japan through the constant practice of “Creation & Innovation” and will strive to build mutual trust with our customers by providing products and services that meet their needs while ensuring compliance with laws and harmony with society.

Basic Measures

Established: October 1, 2008

Revised: September 1, 2022

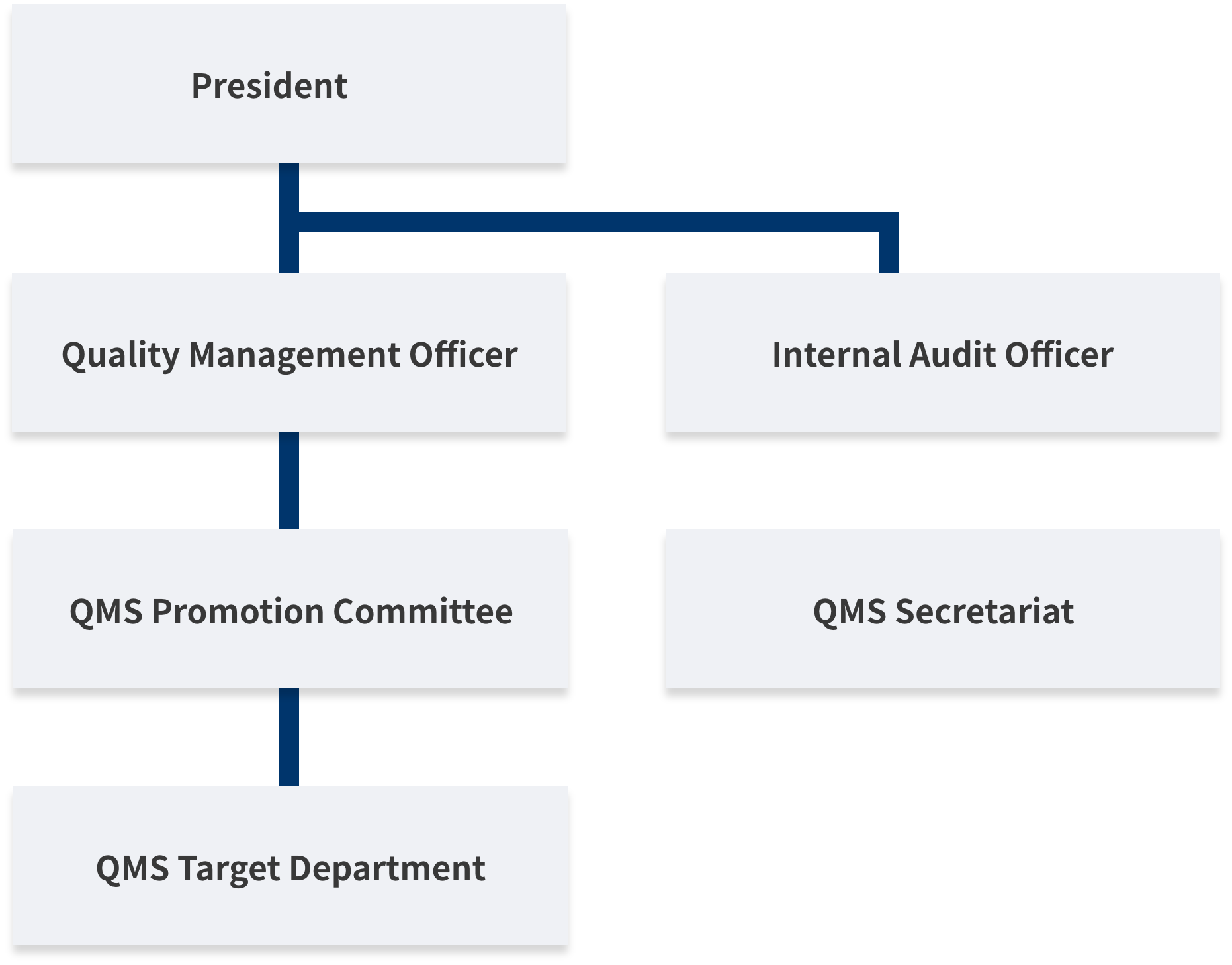

In order to provide quality products and services to our customers, the Glosel Group has established a quality management system based on the Quality Management System (QMS): ISO9001:2015, which is applied to organizations mainly in the technical departments.

In this way, we carry out continuous quality improvement activities in a series of processes ranging from planning, development and design, manufacturing contracting, sales, and service.

Registration organization: Japan Management Association

Registration number: JMAQA-2562

Registration date: March 27, 2009

Registration expiration date: September 19, 2025

Registration revision date: August 21, 2023

Applicable standard: JISQ9001:2015 (ISO9001:2015)

In order to maintain and improve outstanding quality, the Glosel Group has established a QMS education system for employees in departments covered by QMS, and always takes various measures to raise awareness and acquire knowledge. Examples include training for new employees and new members assigned to departments covered by QMS to familiarize them with the basics of ISO9001 and Glosel’s Quality Policy, awareness raising through cross-reading of department standards in each department, and specialized training to acquire necessary knowledge.

The Glosel Group takes measures to ensure the safety of its customers in cooperation with manufacturers it handles. We have established standards for conducting Product Safety Design Risk Assessments for our own products, and we have clarified safety design standards for products to minimize product safety risks, and standards for conducting assessments, which are reflected in our product designs. As a specific example, we establish product safety categories. Then, we conduct a risk assessment according to a pre-defined checklist of items to consider. Subsequently, a cross-functional team of experts is formed to review product safety design and assess risk targets, hazardous conditions, safety measures, and risks.

In the development of Glosel’s own products, design categories are defined through product planning, promotion of product design and development, design review, development of prototypes and mass production prototypes, and transition to mass production. Principles and processing methods are established for common and basic matters in the design and development of hardware and software. At the time of design review of each design category, the parties concerned discuss according to the items to be discussed. With the agreement of the participants, we will move to the next design category and proceed with development.

For the products and parts that make up our products and the packaging materials we purchase, we have established the Standards for the Implementation of Part Certification and apply the certified parts and packaging materials to our products. Quality includes product safety (product liability) and control of chemical substances in products. To ensure reliability, we set quality target levels in accordance with the quality requirements of our customers and determine and conduct reliability tests necessary to meet the target levels.

When quality problems occur after a product or service is delivered to a customer, prompt and appropriate action is required. The Glosel Group responds quickly to quality issues that arise with its customers. Upon receiving a report of a quality problem from a customer, we discuss the cause and countermeasures with the relevant parties. We will consider measures to prevent a recurrence and promptly report to customers and implement them.

The Glosel Group strives to contribute to the development of Japanese industry under the management philosophy, “Creation & Innovation” and complies with all laws and regulations in harmony with society. As the most trusted company, we pursue satisfaction that inspires our customers and aim to achieve both “realization of a sustainable society” and “realization of sustainable growth” through our business activities.

In our efforts, we aim to increase corporate value so as to earn the trust of all stakeholders, including customers, shareholders, employees, and local communities with which we coexist and contribute to the achievement of a sustainable society by addressing social issues.

For inquiries from outside stakeholders, a contact point* is provided on the Company website. Opinions and requests received here are shared with the relevant departments to respond promptly. In addition, we strive to ensure fair and appropriate disclosure of information to institutional investors, individual shareholders, and others.

*Inquiries

| Stakeholder | Theme | Means of communication | Major initiatives in 2022 |

|---|---|---|---|

| Educational and research institutions | • Joint research |

• Joint research of STREAL with Shizuoka University and others |

|

| Employees | • Improvement of the working environment |

• Employee Representative Committee |

• Representative Committee (11 meetings), Workplace meeting (eight meetings), Labor-Management meeting (one meeting) |

| NGO/NPO | • Protection of ecosystems |

• Volunteer activities |

• Voluntary activities using the volunteer leave program |

| Local communities | • Participation in local communities and fulfillment of responsibilities as a corporate citizen |

• Disaster prevention and crime prevention training |

• Social contribution through sports (Japan ParaCanoe Association and Chiyoda Football Association) |

| Shareholders and investors | • Medium to long-term management strategy for sustainable growth |

• General Meeting of Shareholders |

• Financial results briefing session (twice) |

| Suppliers | N/A |

• Calculation and reduction of CO2 |

N/A |

| Government offices and municipalities | N/A |

• Complying with surveys |

N/A |

| Other companies | N/A |

N/A |

N/A |

Considering the entire life cycle of the products and services provided to our customers, the Glosel Group will promote the purchase of products and services with low environmental impact and encourage transactions with business partners that are actively involved in biodiversity and environmental considerations, in order to reduce environmental impact and increase added value.

In the development and manufacturing of our own products, the Glosel Group has established Green Procurement Standards to provide environmentally conscious products to customers by reliably obtaining information on chemical substances contained in products delivered by suppliers and procuring products with low environmental impact. At the same time, we make efforts to appropriately grasp and manage information on chemical substances that need to be communicated (type, content, concentration, etc.), to comply with domestic and overseas chemical substance-related laws and regulations such as the RoHS Directive and the REACH Regulation, and to reduce environmental impact.

GS Green Procurement StandardsPDF

In line with its credo of “Creation & Innovation,” the Glosel Group promotes the research and development of “STREAL” as a “technology trading company” with manufacturing functions.

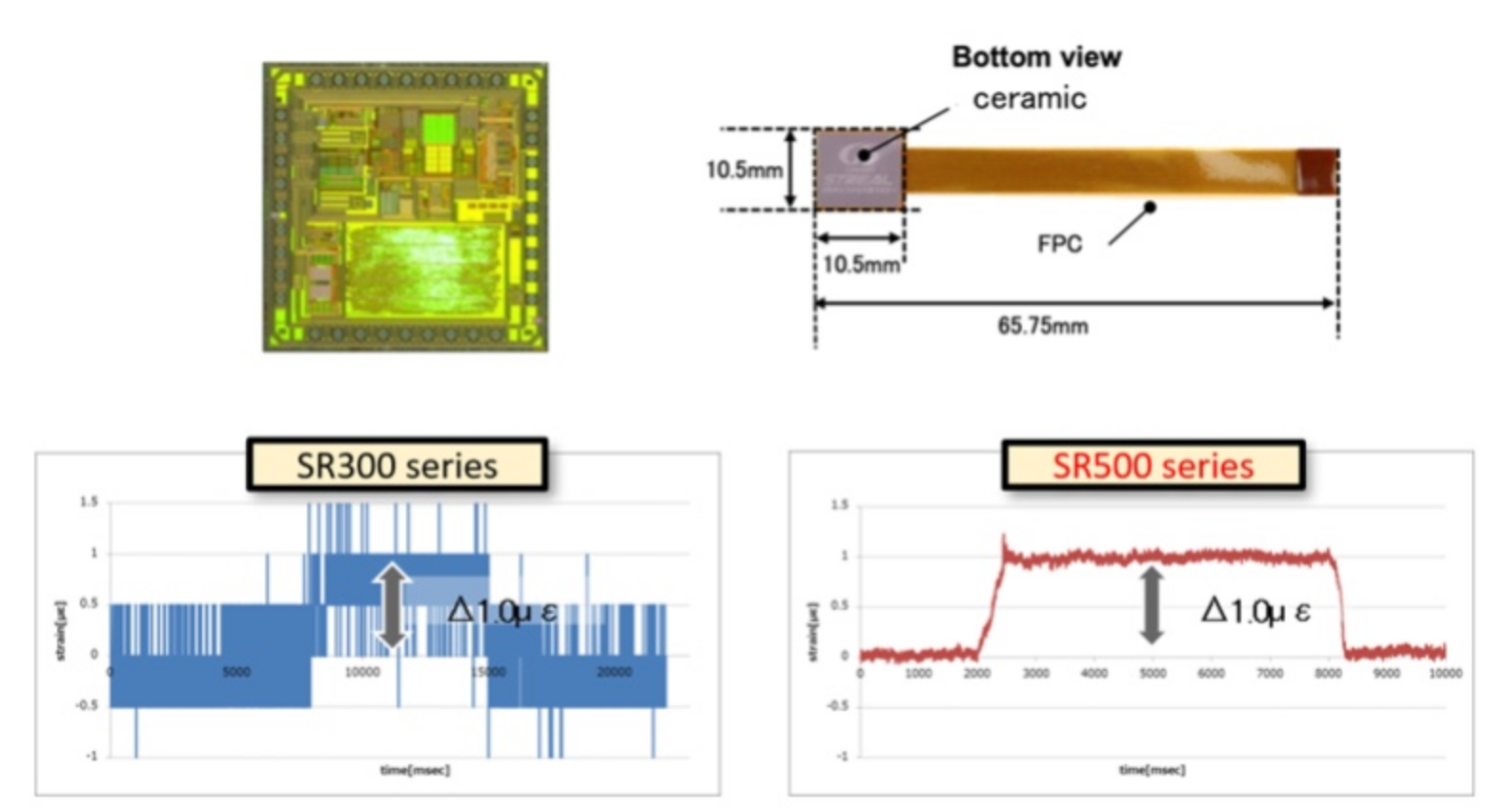

In the Glosel’s own high-sensitivity strain sensor “STREAL” business, research and development is being widely conducted under the themes of “collaboration between industry and academia” and “co-creation in different fields” in order to overcome social issues such as labor shortages, global environmental issues, and improvement of the work environment and to realize a sustainable society.

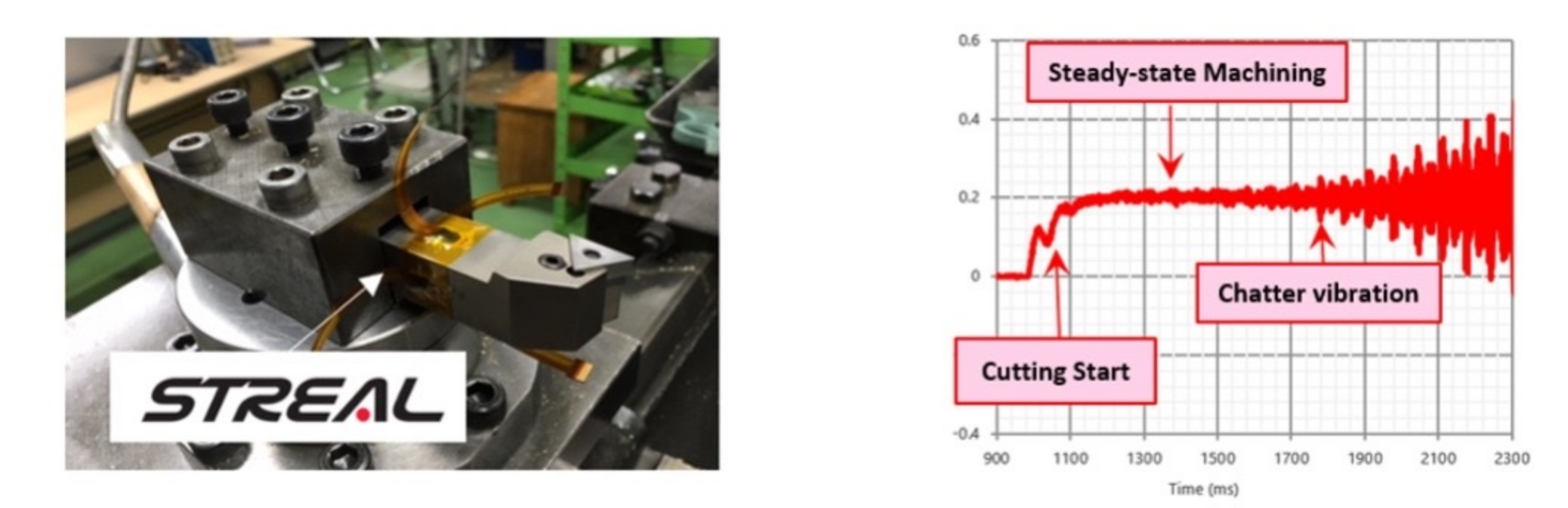

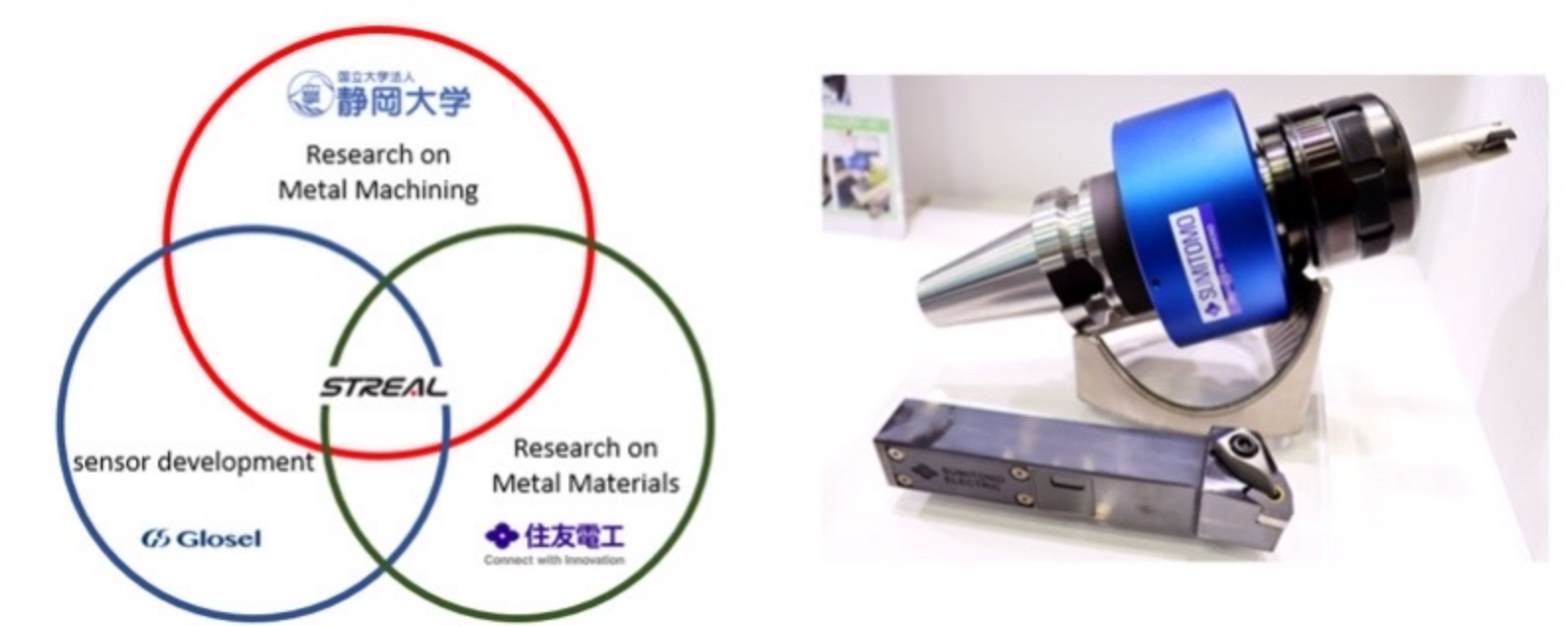

Here are examples of research collaboration with a university and joint development of the STREAL business. In the research collaboration, we provided Sumitomo Electric Industries’ cutting tools and the Glosel’s high-sensitivity strain sensor “STREAL” to Shizuoka University and cooperated in “advanced research on metal working.” The results of this research have been presented at the euspen (international academic society), the Society of Mechanical Engineers, and the Society for Precision Engineering. In addition, a completely new sensing tool with built-in STREAL was developed jointly by Sumitomo Electric Industries and Glosel. The practical application of this tool is expected to enable the DX of cutting processes, which have traditionally relied on the “experience” and “intuition” of craftspeople, and the realization of more advanced machining methods and the passing on of technology.

The Company will continue to contribute to society by creating high-value-added solutions through aggressive research and development activities.

Using this innovative device, we conduct advanced research with universities, research institutes, and manufacturers in different fields.

Because the research and development unit is located in the same division as STREAL’s sales unit and sales engineering unit, we have established a structure that allows us to engage in research and development not only in technical areas but also in consideration of customer needs.

The Glosel Group provides two years of training after joining the company to acquire basic technical knowledge and applied technology. Furthermore, by conducting design and development in accordance with the Company’s own product design standards based on ISO9001, we will develop human resources to create new technologies with an awareness of design quality. In addition, by sharing information such as customer needs held by the sales and sales engineering departments within the division, we develop human resources who can develop not only in the technical area but also in the business area.